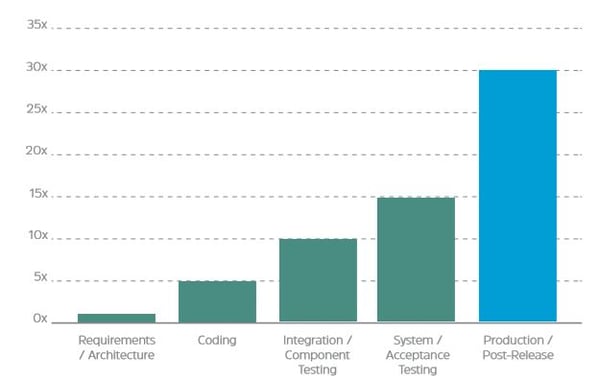

The concept of 'Shift Left' has its roots in software testing, where it refers to the relative cost to fix an error, based on the time of detection. You can see in the graph below that errors which make it through to the final stage of Production/Post-Release stage cost 30 times more to fix than those detected at the initial Requirements/Architecture phase. So the software industry does whatever it can to 'shift left' those errors, and detect them as early as possible.

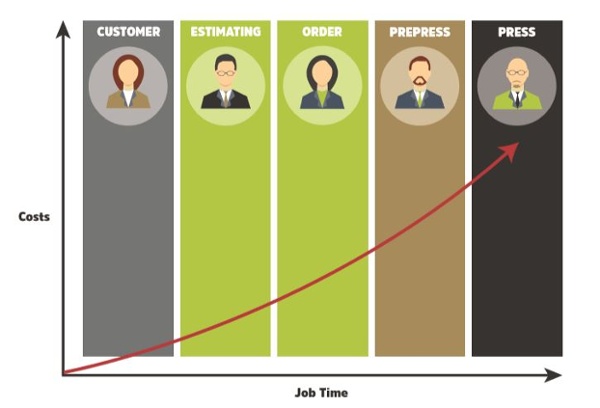

The below is what the Shift Left approach looks like in a print workflow. The red arrow represents the cost to make changes to the job as it goes through the different stages of the business.

The below is what the Shift Left approach looks like in a print workflow. The red arrow represents the cost to make changes to the job as it goes through the different stages of the business.

So to maximize value from each job, printers need to 'shift left' any errors and fix them as early as possible in the workflow. And they will need to make this a permanent solution so that each time this type of job is produced, little or no intervention is required.

So to maximize value from each job, printers need to 'shift left' any errors and fix them as early as possible in the workflow. And they will need to make this a permanent solution so that each time this type of job is produced, little or no intervention is required.

How to shift a problem left

I'm going to explain to you how the shift left approach works with a problem many of you will encounter all the time, I'm sure - incorrect artwork being sent in by the customer.

The customer requests a quote for an A4/8.5x11 leaflet.

The customer requests a quote for an A4/8.5x11 leaflet. - The estimating team provide a quote.

- The customer decides to proceed with the order and sends the artwork over.

- The CSR team hand the artwork over to Prepress who check the file only to discover that it's actually A3/11x7.

- Prepress speak to the CSR team the following day (because they'd already gone home by the time Prepress had got to look at the file) and let them know it's the wrong size.

- The CSR speaks to the customer to ask if the artwork is to be re-sized, or did they actually mean A3/11x7 in the first place? The customer is not happy because they sent the artwork early the previous day and they're only just being told it's wrong.

Shifting this problem left

Our main goal is to move the problem away from Prepress and shift it left to the CSRs, so that any artwork discrepancies are detected before they reach Prepress. In this example, we would do this using technology to implement job structure pre-flighting, specifically an integration between your MIS and Enfocus Switch.

What this would look like:

- Customer requests an A4 quote.

- Estimating oblige and when the artwork is received, Switch compares the size of the artwork to what the MIS is expecting, before sending to Prepress.

- The CSR is alerted immediately of any discrepancies and can contact the client straight away, ensuring that only correct artwork and instructions are passed into production.

I'm sure you'll have realized you could move this even further left by implementing content submission portals for your clients, which automatically check the artwork without involving the CSRs (unless a re-quote is required).

The Shift Left concept is an easy one to understand, but a hard one to implement. You need to have the right people in your business that will recognize the need to do this, as well as have the desire and the skills to do it.

If you're interested in finding out what kind of people you need and how exactly you can go about implementing a Shift Left culture, you can read more of our advice in our Automation Culture eBook.