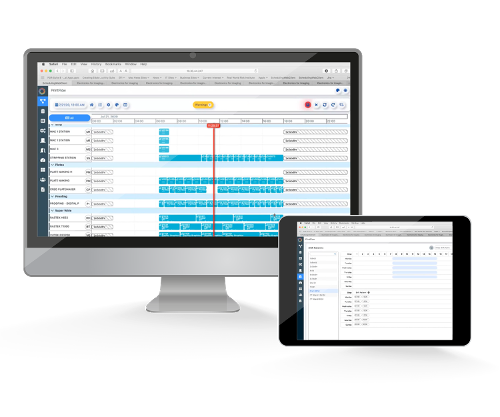

PrintFlow 4D is a fully automated, rules-based scheduling tool that will soon be available to Tharstern customers as a browser-based add-on extra.

The integration will automatically send jobs over from the Tharstern MIS into PrintFlow 4D, which will be auto-updated with changes from within Tharstern or from our Shop Floor Data Capture tool.

Scroll down to find out how more about PrintFlow 4D's features and how it benefits our customers.

WHAT THE INTEGRATION DELIVERS

Switchover considerations

PrintFlow 4D considers the jobs before and after each job and will take this into account when creating the optimized schedule. Device location or substrate size, for example, could affect which device is selected for production.

Ability to add limitations

PrintFlow 4D allows you to add limitations to each of your production devices. So, if you’ve had problems printing with a particular substrate on a particular device in the past, you can tell PrintFlow 4D not to plan jobs with this combination. You can even add customer-based limitations!

Superior optimization capabilities

You can specify a huge amount of criteria for PrintFlow 4D to take into account when optimizing the schedule, including: employee availability, tooling availability, scheduling constraints, job requirements, machine capabilities and material availability. You can be as specific as you like! So if you want to optimize on page widths, for example, just specify this within PrintFlow 4D and the software will automatically group jobs with the same or similar page widths together on one device for optimal efficiency.

Reporting

PrintFlow 4D includes a powerful and customizable Capacity Utilization tool that allows you to look at utilization at the cost centre, department, plant and company levels, and across time periods. Views include: idle time, on time vs late jobs, and lost hours due to switchover.

What-if scenarios

You can compare what-if scenarios to see how jobs and customers are affected by theoretical changes. You can evaluate which jobs become late if you add a rush job, for example, or which behind-schedule jobs would ship on time if overtime was added.

Identify bottlenecks and weak links

You can uncover any weak links by identifying the number of jobs that have been passed to a device that can’t be started on time. The devices with the most weak links are likely creating serious bottlenecks for you and by identifying which they are, you can take action!

What you'll need

- The latest version of the Tharstern Desktop

- The latest version of PrintFlow 4D

- *UK only – this integration is not available for users of Estimating Classic

Want to get a demo of PrintFlow 4D and see how this will help optimize your print business?

Book a session in our online calendar.