Is industry 4.0 relevant for my print business?

You’ve probably heard discussions about industry 4.0, we talked about it a lot here at Tharstern, but maybe you’re a little confused about exactly what it means. For those of you interested in knowing a bit more about the concept and how it fits in with your print business, we've got a great webinar for you to watch! Here's a summary of some of the main points to whet your appetite, and a link to the full session at the end.

The themes of industry 4.0

At the heart of industry 4.0, there are themes that differentiate it from previous revolutions and highlight the main ideas surrounding it. These are…

- System Integration - This is an obvious one and refers to the integration technologies that connect the disparate parts of a company’s tech stack together e.g. API, JDF and XML, as well as third party middleware solutions such as Zapier.

- Big data - This refers to the analysis of extremely large and complex data sets to reveal patterns, especially relating to human behaviour. There is apparently a great opportunity for printers to apply the patterns and trends unearthed from this analysis to variable data printing. For example, analysing data from various different sources (CRM data + emails received + past estimates/orders etc) to better understand a client’s wants, needs and preferences, and then using this to personalize direct mail and advertising.

- Analytics - There’s loads of valuable information inside an MIS, and if that MIS has an API, printers can make the most of this by hooking up their solution to analytics solutions such as Microsoft’s Power BI or Qlik to help them really delve into their business operations and make more informed decisions.

- Simulation and virtualization - Simulation is used in MIS solutions such as Tharstern to compare the different production routes available for a particular product specification and present the most cost-effective method of production to the user. Virtualization can be used in a similar way (and indeed some of our customers already do this) by adding a virtual press or piece of equipment, so they can see how it affects their costs and help them make a purchasing decision.

- Internet of things - IoT technologies for the printing industry tends to focus mainly on inventory traceability, where raw materials, WIP and finished products are tagged with RFID tags to provide real time visibility of the printing operations. RFID technology can also be used to monitor equipment such as conveyors, trucks, or forklifts.

- The cloud - Cloud technologies are becoming more popular as an option to provide remote access to employees working off-site. This can present some challenges when integrating on-premise technologies such as printing presses, with cloud solutions. A hybrid approach is often employed as a solution in the printing industry.

- Cyber security - The move to online software such as Cloud Technologies has led to an increased need to implement security solutions, and this is relevant to every industry.

- Autonomous robots - Although robotics is in its early stages in the graphic communications industry, there has been some adoption of machines that move materials to the press and in the warehouse for picking and inventory control.

- Augmented reality - One of the most popular uses of augmented reality for managing a business, is to layer data visuals to what we can see with the naked eye using RFID tags e.g. to show WIP location on the production floor, to show stock quantities in a warehouse, or perhaps adding a heads-up display to the fork lift driver in a warehouse so they can see where the stock location is.

- Additive manufacturing - 3D printing is typically used in manufacturing to create working prototypes or replace parts, but in the printing industry it can be used to diversify and provide one-off packaging products.

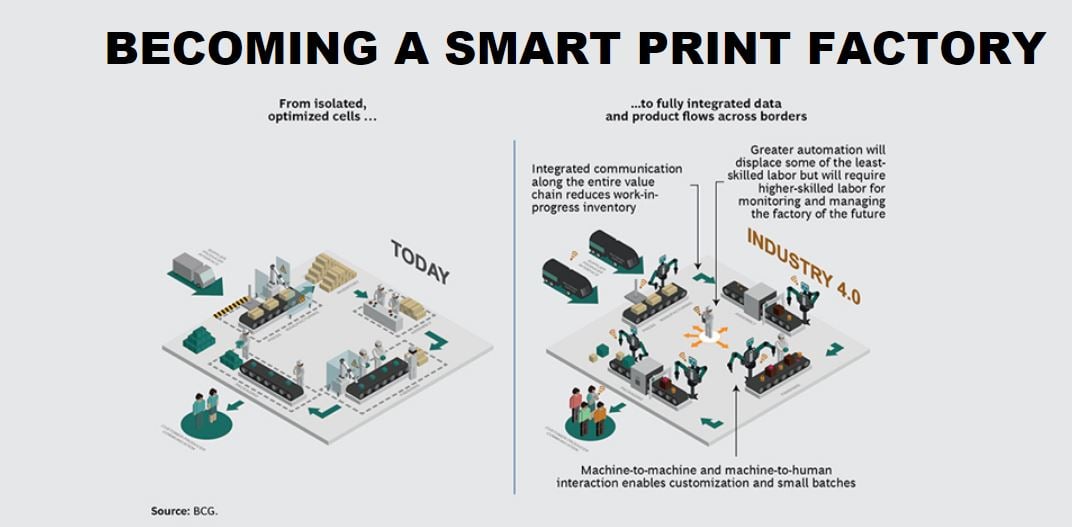

Becoming a smart print factory

In the webinar we also explain and discuss the concept of a Smart Factory - a factory that uses all the above technologies and allows data to be constantly shared and analyzed through the connection of machines and production systems. This illustration from The Boston Consulting Group attempts to illustrate the difference between today's factories and the smart factories of the future. By automating repetitive tasks and connecting processes together, presses can become less reliant on the operators, freeing up time for employees to focus on more complex and innovative tasks that could win you more business.

What printers need to achieve with Industry 4.0 technologies

Our webinar panel had an interesting discussion about how much automation can be achieved in an industry where every job is different, and also how we avoid the commoditization of our products by introducing too much automation. They concluded that printing companies definitely should take advantage of as many Industry 4.0 technologies as possible, while investing in their people so that they can achieve:

- The ability to flex and scale as change occurs.

- An exceptional experience for customers.

- To innovate with new products and services.

- Continuous improvement of systems and technologies.

- Becoming bionic print companies.

Becoming a bionic print company

Of all the objectives above, the last one is key – to become a bionic print company. Much like the Six Million Dollar Man (google it if you’re too young!) companies need both the skills of humans and the processing power of machines in order to evolve in line with industry 4.0. They cannot, in fact, achieve the other four objectives without achieving this. This was the final conclusion from the experts in the webinar, and they finished with the three key things that a printing company needs to do to become bionic:

Step 1: Investigate and implement technology - you need to consider all of the Industry 4.0 technologies available to you and continuously implement new applications.

Step 2: Invest in people and culture - you need people on your team who understand these new technologies and who are excited to apply them to your business. You also need to take away the mundane tasks from the rest of your team, leaving them to focus on the more rewarding activities that add value to your business.

Step 3: Make technology part of your team - you then need to merge these two aspects of your business (people + technology) together, and we’ve covered this topic in more depth in this article.

If we’ve intrigued you and you want to watch the full discussion that covers additional topics to the ones covered in the article, you can get access to the webinar: Is Industry 4.0 relevant for my print business.

Share this

You May Also Like

These Related Stories

6 best podcasts for the printing industry

Why you should treat your technology like an employee