Fulfilling bulk orders that contain both in-stock and manufactured items can be pretty time consuming. A customer sends you a huge spreadsheet and you’re faced with the dreaded task of sorting through all the data and manually processing it.

Sound familiar? Well, by streamlining this process, you can remove those time-consuming manual tasks and work faster and smarter. Every MIS will handle this differently, but here is how you can carry out this process using Tharstern.

Step one: Processing orders using a CSV file and a hot folder

Assuming the spreadsheet provided by your customer includes all the key information (quantities, delivery addresses, etc), you can quickly import this data into your MIS by dropping the CSV file into a hot folder (a network folder that’s monitored by the MIS, so it instantly knows when new data has been placed into it). The MIS will then process this data and create the jobs for each line item.

Step 2: Automating allocation

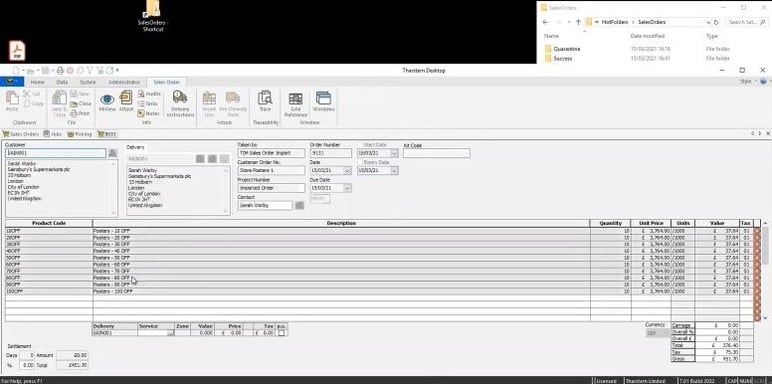

Once the MIS has processed the spreadsheet data, you’ll be able to see each of the order lines within the Sales Order tab. You can also see that the MIS has recognized which order lines need to be manufactured and which need stock allocating to them.

The first thing we’re going to do to fulfil this order is head to the Jobs List within the Sales Order tab, where you will see a list of all the items that need manufacturing. You can multi-select these items and process them in the usual way, sending them off to be manufactured.

%20jpg.jpg?width=864&name=Automating%20allocation%20(2)%20jpg.jpg)

The MIS will then allocate those manufactured jobs to the relevant order lines in the Sales Order, ready for picking and packing.

%20jpg.jpg?width=865&name=Automating%20allocation%20with%20quantities%20(3)%20jpg.jpg)

Step 3: Simplifying the pick & pack process

When you’re ready to get the order out the door, you can select all the items in the job, create a picking list and alert the warehouse operator of the task. Using our Mobile Inventory tool, the warehouse operator can access this list using a handheld device (such as a smartphone or smart barcode scanner) to identify the materials and quantities they need to pick.

For each item, the warehouse operator will need to scan both the stock item and the location to confirm the picking. The MIS will be updated automatically and show the item as being picked.

%20jpg.jpeg?width=307&name=Mobile%20inventory%20pick%20%26%20pack%20(4)%20jpg.jpeg) Once all items have been picked, you can use the MIS to arrange the courier delivery and process the invoice.

Once all items have been picked, you can use the MIS to arrange the courier delivery and process the invoice.

A final word

So, what could have been a complex process has been simplified by following these three easy steps, making it much more slick and scalable.