If you're a production planner, you've probably been presented with certain scenarios that make you want to tear your hair out. In this article we're going to give you some practical solutions to the 3 most common of these.

1. How do I reserve enough space to schedule projects that we haven’t won yet?

Sometimes your sales team might want you to reserve time in the production schedule for an important or urgent order that they're hoping to secure. But is that even possible when you don't have a job to work with?

The short answer is yes! Different MIS solutions will deal with this in different ways, but most of them will allow you to look for provisional jobs and insert them. Here's how we do that in the Tharstern MIS.

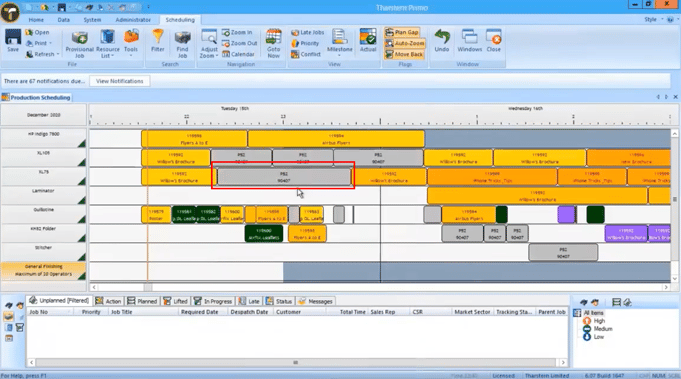

Start by selecting the ‘Provisional Job’ option in the toolbar and search for your project title or estimate number. Once selected, it’ll drop into the unplanned list (at the bottom of the screenshot below) and you can drag and drop it into the planner area. It’ll automatically be placed into the schedule of each of the required resources and will display in grey to differentiate it from the other planned jobs.

If the order is won, the job will appear back in the unplanned list where you’ll be able to merge it with the provisional job you inserted earlier.

2. What if I have more machines than people to run them?

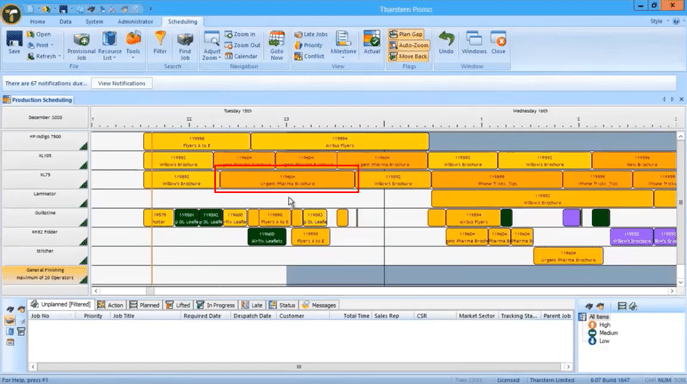

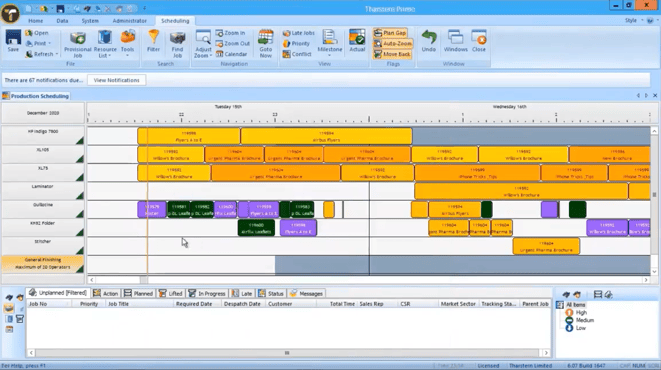

So you have your jobs planned in, but what happens when you don’t have enough people to man the machines for the whole shift? Well in this scenario, you need to plan for people, rather than machines and you can use your scheduling board to do this! Because the job is split into different processes across the planner, you can use colour coding to assign each process to individual operators. This makes it clearer who will be working on which part of the job and when they’re needed.

3. How can we manage operator resource to help us deal with very large jobs or to get urgent jobs out on time?

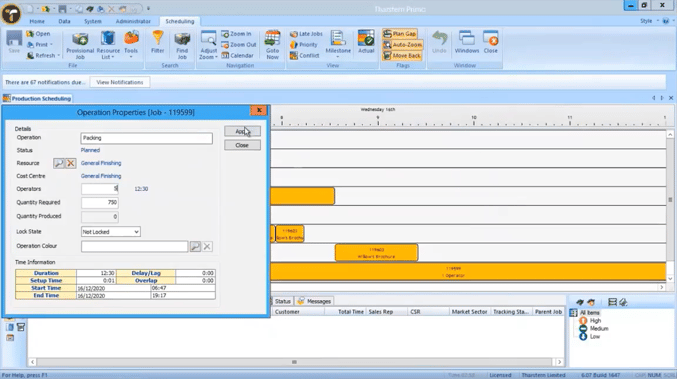

Production planners sometimes have to deal with particularly big jobs that take up a lot of resource, particularly in the finishing department. And sometimes they have to try and tweak the planned schedule to ensure that an urgent job goes out on time. The obvious way to resolve this would be to assign more operator resource to the process, perhaps by taking on casual staff to help finish the job. Does that mean you have to manually adjust and rearrange everything on your production schedule to accommodate these changes? Not at all, all you need to do is increase the number of operatives required for the job (via the ‘Operation Properties’ option in Tharstern’s case), and the length of time needed to carry out that process will automatically be reduced. This will help you get your job out on time, or clear space on the planner for you to add your urgent job.

Yes, these situations can be stressful, but they don’t have to be. Put these solutions to the test and you’ll feel a weight lifted off your shoulders! If you’d like a more in-depth run through of these solutions, take a look at the video below.